PUT DOWN THAT RUBIK’S CUBE…

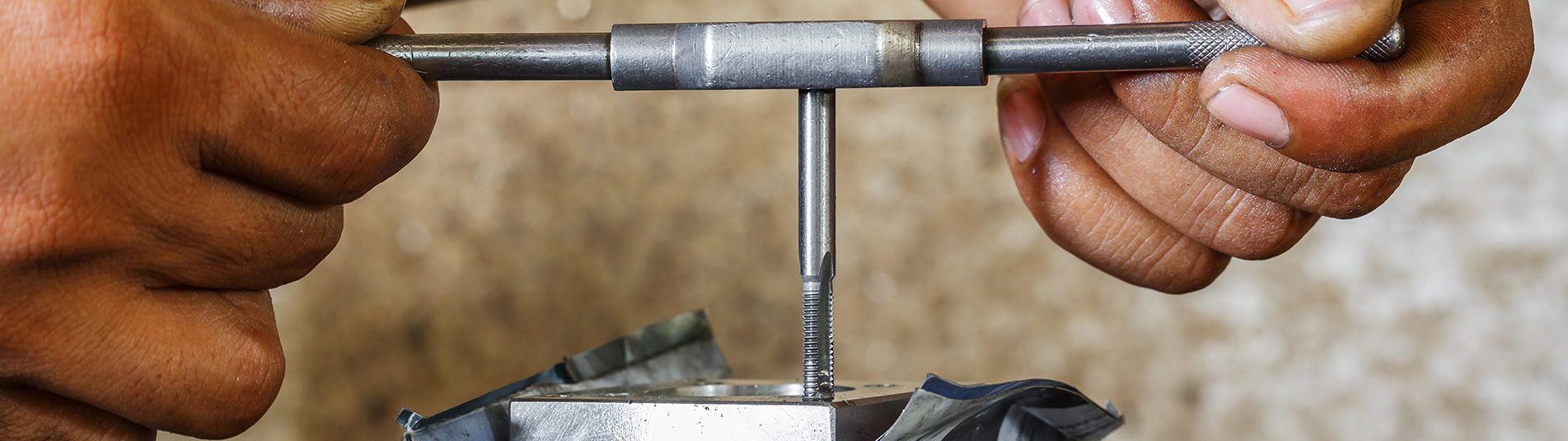

…And pick up a machine die.

More often than not, manufacturing machinery needs a custom built tool or “die” to cut / shape the part or product you’re trying to make. As a Tool & Die Maker, you put together a variety of tool parts and different metals to assemble a die (essentially a custom mold that presses metal into a very specific shape). Almost like a 3D jigsaw puzzle, each die is unique and has to match the engineer’s specifications for a part or product exactly. Because such precision is required, you will also test tools and dies to ensure they are working correctly, and you will measure the finished parts to make sure they match the technical drawings. Day to day you will analyze blueprints for parts, build the tools / dies, install and test them in machinery, and verify that they are producing the part correctly.

Back to browsing jobs

Back to browsing jobs